Structural Safety Audit/ Structural Assessment / Initial Safety Audit for Structural Safety.

Initial Structural Integrity Assessment firm in Bangladesh

EMS offers structural Safety audits to ensure that Buyer and Factory Owner’s industrial and commercial premises are safe, up and Flow to relevant Standard codes as Like (BNBC,RSC,Primark, Nirapon,etc) Standard, and present no Risk to your factory for employee life and health.

Types of Safety Audit.

Initial Safety Audit is more important for Every Industrial factory and all Commercial Building Need their property and life safety. There are many more types of safety insure a good reputed industrial and commercial factory/building authorities as like

- Structural Safety Audit

- Electrical Safety Audit

- Fire Safety Audit

- Energy Efficiency Audit

- Environmental Impact Assessment audit

- Social Audit etc.

There are many more Safety and Compliance audits Held in our Industrial Sector. EMS Engineering Technologies Provide all type of safety audit Service with a good reputation. Now we discuss the Industrial Building Safety audit process and its Importance.

Process of Structural Safety Audit

A structural Safety Audit is totally related to a building and factory premises any kind of concrete and steel or other structure, This audit purposes min’s Structural safety like visiting existing structures physically and any deficit find out and solved. If your factory safety audit process and report quality are maintained by Byer standards you can continue your factory production.

EMS Following Structural Audit Process

The following activities and sequences will be followed during the initial inspection:

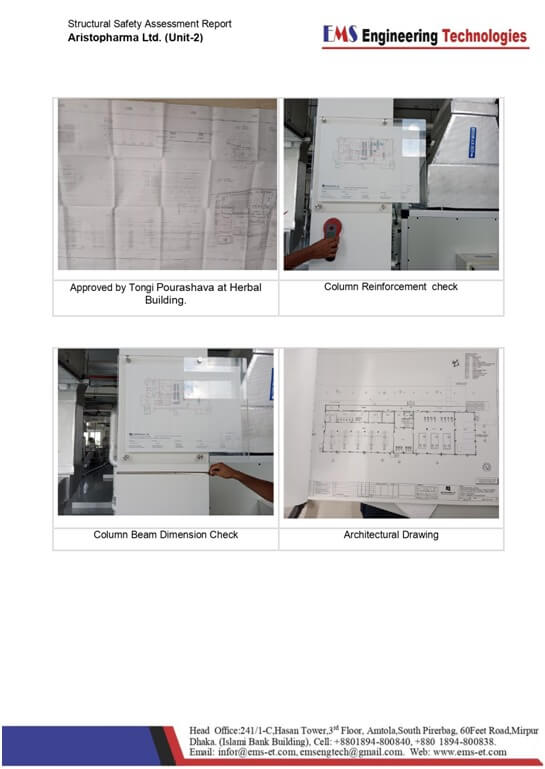

- Review all As-Built Drawings showing structure, loading, elements, dimensions, levels, foundations, and framing on Plan, Section, and Elevation drawing

- The engineering team is reviewing all supporting calculations with a model-based design check to assess the safety and serviceability of the building against loading as set out in BNBC-2006/2020 or Byer (RSC. Nirapon, Primark, VF Asia, KIB, etc) guided Lower rate provisions can be applied in accordance with the Tripartite Guidelines following international engineering practice and justification for these lower rate provisions must be made.

- Review all reports on engineering tests carried out to justify material strengths and reinforcement content in all key elements studied.

- Detailed load plans will be verified for each level showing current and potential future loading with all key equipment items shown with associated load

The Engineering team will review the assessment report which covers the following:

- As-Built drawings including:

- Plans at each level calling up and dimensioning all structural component

- Cross-sectional drawings showing structural beams, slabs, floor-to-floor heights, roof build-ups, and basic design information of the structure

- As-Built drawings including:

2. Results of testing for strength and material.

- Details of loading, inputs, and results of a computer model.

3. Commentary on adequacy/inadequacy of elements of the structure

4. Floor Load plan

Structural Audit Investigating Documents List

- Geotechnical (soil) investigation report

- Previous assessment report (if any)

- Architectural Drawing

- Structural Drawing

- As-built drawing (authentic)

- Construction History (timing of construction phases)

- Approval letter + Drawing

- Factory Inspector’s Approval

- Environmental Clearance Certificate

- Fire Department’s Clearance

EMS Structural Audit Report Step:

- Check all Building Construction Legal Design, Drawing documents Like Approval Drawing, DIFE,RSC,Nirapon,Primark Approval etc.

- Check and verify your Other Authority Clearance BFSCD, Aviation Authority etc.if required

- Verifydesign drawing to relevant code and Standard.

- Check and verify all Structural Member to Find out Mitch match design between existing Structures.

- Check full Factory Building/ Shed Structure find out design and construction missing.

- Check all building/ shed visualize Construction Lack.

- Check un documented and un safe Existing Construction Lack

- Verify All Material Quality and Strength for design drawing Standard

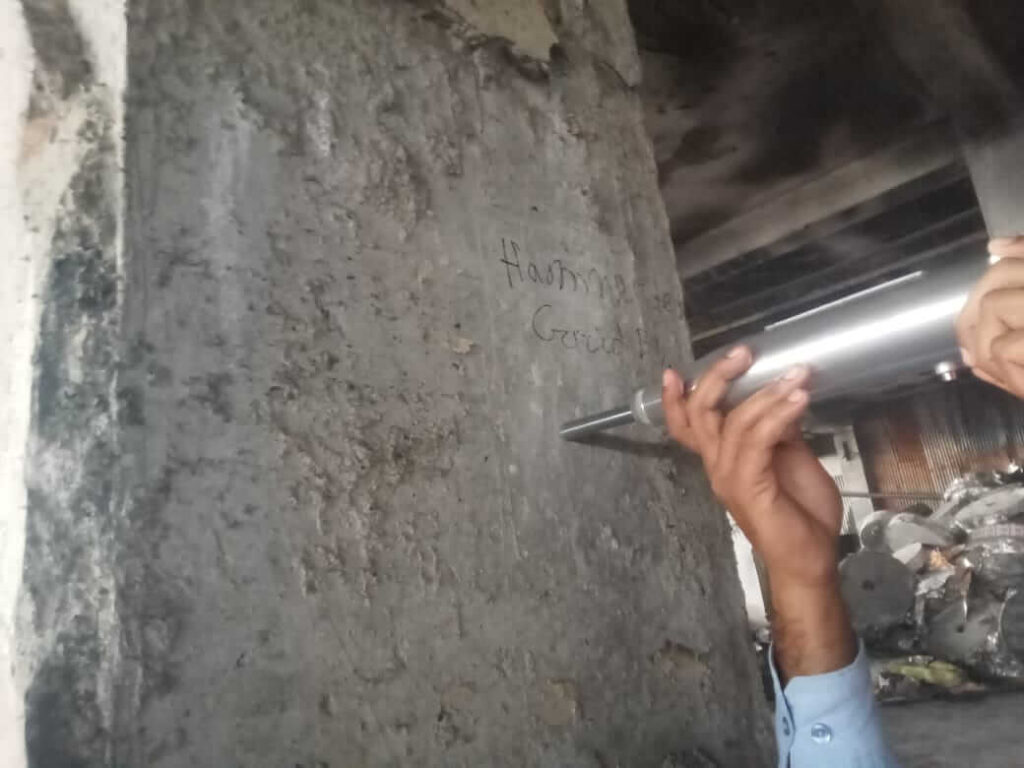

- Doing NDT Test for Confirming Concrete and Reinforcement Quality.

- Finally Calculate FOS to confirm Building/Shed safety Position.

EMS Flowing Assessment Report Some Step as Like: