Ferro scanning test in Bangladesh

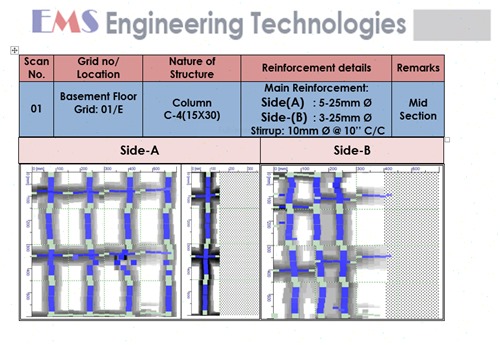

The Ferro Scan Test is also known as Electromagnetic Cover Measurement. This test is one of the non-destructive tests among others through that the positions, as well as the quantity of reinforcement steel located inside concrete members, can be determined easily. EMS Engineering technologies conduct Ferro scanning test in Bangladesh. This test can also be used to inspect old buildings which do not contain structural drawings. On the other hand, it may only contain outdated drawings that may not be included in any renovations that happened later. The Ferro Scan Test or Electromagnetic Cover Measurement can also be used to find out the current positions as well as the quantity of reinforcement steel located in concrete members. Here, the load-carrying capacity of the structures can be determined using the data which is used earlier.

Ferro/ Rebar Scanning/ Reinforcement Scanning type of Using Purpose.

- Check Reinforcement Quantity

- Check Reinforcement Placement

- Check Reinforcement Quality

- Check Reinforcement Dia / Size Confirmation

- Check Reinforcement Spacing both side

- Check Clear cover of reinforcement to Concrete

- Check other unethical element like cable, Pipe Etc.

What are the components used in the Ferro scanning test in Bangladesh?

The Ferro Scan Test operates through the principle called the electromagnetic field. An electromagnetic field becomes released by the emitter head. After the emitter head has been placed closer to any reinforcement area then the reinforcement bar along with the induction properties will interrupt the electromagnetic field. Thus, the location where the electromagnetic field has been shown to be interrupted may have the ability to represent the area of the reinforcement steel. So, the components used in the Ferro scanning test in Bangladesh are-

Data collection device or the scanner: This scanner allows data collection using its passage on the concrete surface so that it can be analyzed. In the case of a device that doesn’t have any physical links with the display monitor and therefore it allows fully independent usage of the device. Some other usages of this device are-

- The device is portable in most cases.

- In the most adverse conditions it gives the right details. The conditions such as- suspended readings, places those are hard to reach or confined spaces.

- Provide details which are particularly fruitful.

Data analysis screen: The “scanner” that has been transferred by infrared to the monitor earlier obtain the information and present the data storage related issue or ready to review. The quality assessment of the analysis of the reading carried out by the monitor can be aimed for. It also allows the results that provide immediate information of work which are in progress. Through the monitor, it becomes possible to perform-

- A full analysis or spot reading, such as- setting the position, depth or diameter.

- Also additionally audio information can be recorded.

- It enables easy future identification including data analysis or reporting.

Conclusion

Now it’s known that Ferro scanning is a non-destructive imaging tool that provides information regarding existing reinforcement. It performs it by determining its position, number, diameter, and coverage depth in 2D. It can also determine the costs and risks associated with crossing or reaching the structural perforation bars which should be avoided. We do the Ferro scanning test in Bangladesh. We’ve skilled engineers who have the ability to do the test efficiently.