UPV (Ultrasonic Pulse Velocity) Test in Bangladesh

Ultrasonic Pulse Velocity (UPV) test is a non-destructive testing method widely used to assess the quality and strength of concrete structures. The UPV test measures the velocity of sound waves through concrete, which is related to its compressive strength. It can help identify structural defects or anomalies, such as cracks, voids or delaminations. Furthermore, it provides valuable information about the structure’s overall condition and helps determine if maintenance or repair work is needed.

In Bangladesh, where many buildings and infrastructures are made of concrete due to its low cost and availability, UPV testing has become an important tool for engineers and contractors working on construction projects. Government agencies and private companies have widely adopted this testing method to ensure compliance with building codes and safety regulations.

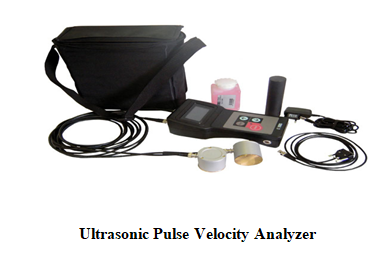

Equipment for pulse velocity test:

The equipment consists essentially of an electrical pulse generator, a pair of transducers, an amplifier and an electronic timing device for measuring the time interval between the initiation of a pulse generated at the transmitting transducer and its arrival at the receiving transducer. Two forms of electronic timing apparatus and display are available, one of which uses a cathode ray tube on which the received pulse is displayed in relation to a suitable time scale, the other uses an interval timer with a direct reading digital display. Time equipment should have the following characteristics. It should be capable of measuring transit time over path lengths ranging from about 100 mm to the maximum thickness to be inspected to an accuracy of ± 1%. Generally, the transducers used should be in the range of 20 to 150 KHz although frequencies as low as 10 KHz may be used for very long concrete path lengths and as high as I MHz for mortars and grouts or for short path lengths.

High frequency pulses have a well-defined onset but, as they pass through the concrete, become attenuated more rapidly than pulses of lower frequency. It is therefore preferable to use high frequency transducers for short path lengths and low frequency transducers for long path lengths. Transducers with a frequency of 50 KHz to 60 KHz are suitable for most common applications.

Measuring with Ultrasonic Instrument:

The Ultrasonic Instrument can be used several applications including the following:

- Pulse velocity measurement

- Path length measurement

- Surface velocity measurement

- Crack depth measurement

- Estimating the dynamic elastic modulus of samples (with the shear wave transducer)

- Ultrasonic Instrument only. Estimating compressive strength using pulse velocity alone or in combination with a rebound hammer.

Testing Equipment Details Ultrasonic Pulse Velocity

Name: Control PULSONIC Ultrasonic Pulse Analyzer |

Country of Origin:Italy |

Model No: 58-E4800 |

Frequency: 50/60 Hz |

Calibration Time: 57.9 micro second |

Transmitter Output: 1200 V |

Reference / Standards

- ASTM C-597-“Standard Test Method for pulse velocity Through Concrete”

- BS EN 12504-4:2004 ( formerly BS 1881-203) “Determination of Ultrasonic pules velocity”

- ASTM D2845-08 “Standard test Method for Laboratory Determination of pules velocity and Ultrasonic Elastic Constants of Rock”

- IS13311 Part 1: “Non- Destructive Testing of concrete Methods of Test Part 1-Ultrasonic pulse Velocity”